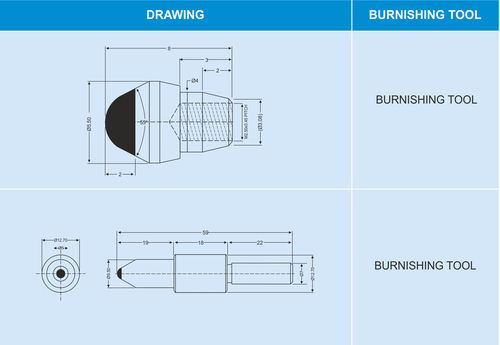

Face Burnishing Tools

MOQ : 10 Packs

Face Burnishing Tools Specification

- Cutting Speed

- Up to 60 m/min

- Cutting Force

- Low

- Operate Method

- Manual or CNC operated

- Machine Type

- Lathe, milling or CNC

- Features

- Mirror finish, high wear resistance, easy installation

- Cutting Accuracy

- High precision

- Length

- Standard lengths: 80 mm, 100 mm, 150 mm

- Coating

- Uncoated

- Hardness

- HRC 48-58

- Shape

- Round Face

- Tool Type

- Burnishing tool

- Cutter Type

- Burnishing roller

- Cutting Capacity

- Suitable for light to medium finishing

- Operation Type

- Burnishing

- Material

- Premium quality alloy steel

- Diameter

- Range: 10 mm to 150 mm

- Maximum Torque

- Variable based on application

- Processing Type

- Surface finishing

- Cooling Type

- Dry and Wet compatible

- Replacement Blades

- Available on request

- Surface Finish Achieved

- Up to Ra 0.2 µm

- Maintenance

- Low, periodic cleaning recommended

- Packaging Type

- Protective hard case

- Application

- Face finishing of shafts, rods, and discs

- Compatible Materials

- Steel, Stainless Steel, Aluminum, Brass

- Min/Max Workpiece Diameter

- 16 mm - 60 mm

- Weight

- Approx. 0.8 kg per tool

About Face Burnishing Tools

Discover the exquisite Face Burnishing Tools, engineered for breathtaking performance and spectacular results. Achieve mirror-like surface finishes up to Ra 0.2 m at the lowest pricegrab yours now and personalise machining for your needs. Suitable for shafts, rods, and discs in steel, stainless steel, aluminum, and brass, these tools support wet or dry cooling and suit diameters between 1660 mm. Delivered in a protective hard case, they boast premium alloy steel construction, low maintenance, and easy installation. Replacement blades are available upon request. Made in India for global export.

Versatile Applications and Exceptional Features

Face Burnishing Tools excel across various industries, perfect for use on lathes, mills, or CNC machines for light to medium surface finishing tasks. They are suitable for automotive, aerospace, and general manufacturing applications. Benefit from high wear resistance, low cutting force, and remarkable cutting speed. The tool adapts to different diameters and materials, features a round face shape, and is easy to install, making it a must-have for professionals demanding precision and spectacular surface quality.

Sample Policy and Export Markets Overview

Explore our Face Burnishing Tool samplesavailable for testing before purchase at attractive rates. We efficiently dispatch samples to domestic and international customers. Our primary export markets include Asia, Europe, Africa, and the Middle East, with each shipment securely packaged for safe transit. Whether you are a trader or exporter, our support team guides you through every step, ensuring seamless sample delivery and helping you discover the advantages in diverse industrial applications.

Versatile Applications and Exceptional Features

Face Burnishing Tools excel across various industries, perfect for use on lathes, mills, or CNC machines for light to medium surface finishing tasks. They are suitable for automotive, aerospace, and general manufacturing applications. Benefit from high wear resistance, low cutting force, and remarkable cutting speed. The tool adapts to different diameters and materials, features a round face shape, and is easy to install, making it a must-have for professionals demanding precision and spectacular surface quality.

Sample Policy and Export Markets Overview

Explore our Face Burnishing Tool samplesavailable for testing before purchase at attractive rates. We efficiently dispatch samples to domestic and international customers. Our primary export markets include Asia, Europe, Africa, and the Middle East, with each shipment securely packaged for safe transit. Whether you are a trader or exporter, our support team guides you through every step, ensuring seamless sample delivery and helping you discover the advantages in diverse industrial applications.

FAQs of Face Burnishing Tools:

Q: How do Face Burnishing Tools improve surface finishing quality?

A: Face Burnishing Tools employ high-precision rollers to uniformly refine surfaces, achieving exceptional mirror finishes up to Ra 0.2 m, which enhances both appearance and performance of machined parts.Q: What materials can these burnishing tools be used with?

A: They are compatible with steel, stainless steel, aluminum, and brass, making them versatile for a range of industrial finishing tasks.Q: When should I consider replacing the blades on this tool?

A: Blades should be replaced when you notice a decline in finishing quality or significant wear, and replacement blades are conveniently available on request.Q: Where can these tools be used in terms of machine type?

A: These tools are suitable for manual operation on lathes, milling machines, or CNC machines, offering flexibility across various manufacturing setups.Q: What are the benefits of using Face Burnishing Tools compared to traditional abrasive methods?

A: They deliver a superior, mirror-like finish with low cutting force, reduce the need for abrasives, decrease operational costs, and offer faster, cleaner processing of parts.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cobalt Cutting And Threading Tools Category

Dimond burnishing tools

Minimum Order Quantity : 10 Packs

Shape : Cylindrical Body with a Tapered Head

Material : Others, Tool Steel Body with Polycrystalline Diamond Tip

Dc Grinding Wheel

Minimum Order Quantity : 10 Packs

Shape : Depressed Center (DC)

Material : Others, Aluminum Oxide

HSS TAPS AND DIES

Minimum Order Quantity : 100 Pieces

Shape : Round

Size : Sizes Available

Product Type : HSS TAPS AND DIES

Usage : Industrial

Material : Others, Metal

Counter Cobalt Cutting Tools

Minimum Order Quantity : 100 Pieces

Shape : Round

Size : Sizes Available

Product Type : Counter Cobalt Cutting Tools

Usage : Industrial

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS