Dimond burnishing tools

MOQ : 10 Packs

Dimond burnishing tools Specification

- Operation Type

- Finishing and Burnishing

- Cutting Capacity

- Suitable for 0.5mm - 50mm Surface Finishing Range

- Drill Bits Types

- Burnishing Tool Bits

- Cutting Force

- Low to Medium (For Surface Finishing)

- Cutting Accuracy

- 0.01 mm

- Coating Type

- None (Natural Diamond Tip)

- Coating

- Not Coated (Industrial Diamond)

- Length

- 100mm - 150mm (Varies by Model)

- Tool Type

- Diamond Burnishing Tool

- Features

- High Wear Resistance, Precise Surface Finish, No Material Removal

- Cutter Type

- Diamond Tip

- Machine Type

- Lathe, CNC Turning, Manual Machines Compatible

- Material

- Tool Steel Body with Polycrystalline Diamond Tip

- Operate Method

- Manual or CNC Operated

- Cutting Speed

- Up to 120 m/min (Recommended)

- Hardness

- Diamond Hardness, ~ 6000-8000 HV

- Shape

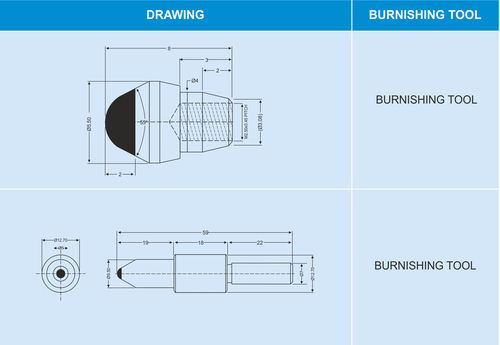

- Cylindrical Body with a Tapered Head

- Diameter

- 6mm, 8mm, 12mm (Customizable)

- Maximum Torque

- Not Applicable (Hand or Low Torque Machine Usage)

- Processing Type

- Surface Enhancement (Burnishing)

- Tool Life

- Extremely Long (Depends on Application)

- Suitable Workpiece Materials

- Steel, Stainless Steel, Cast Iron, Aluminum, Brass

- Use in Automation

- Suitable for Automated Production Lines

- Cooling Requirement

- Dry or Minimal Coolant

- Replacement Tip

- Interchangeable Diamond Tip Available

- Application

- Burnishing, Polishing, Surface Refinement

- Mount Type

- Straight Shank

- Repeatability

- High, Consistent Finish

- Surface Roughness Achievable

- Up to Ra 0.05 µm

About Dimond burnishing tools

Experience the sublime performance of our top-rated Diamond Burnishing Tools-crafted to provide magnificent surface refinement with first-class reliability. Achieve surface roughness as low as Ra 0.05 m on a variety of materials including steel, stainless steel, cast iron, aluminum, and brass. These first-class tools offer exceptional repeatability, extremely long tool life, and a consistent, high-precision finish. Ideal for manual or CNC operations, their interchangeable diamond tips and robust tool steel bodies ensure lasting excellence. Grab yours today at a special rate for optimal performance and efficiency.

Versatile Use and Magnificent Build Quality

Our Diamond Burnishing Tools are designed for both manual and automated applications, making them ideal for use on lathes, CNC turning centers, and manual machines. Featuring a tool steel body fitted with industrial-grade polycrystalline diamond tips, they provide sublime wear resistance and precise, repeatable results. Use them for professional burnishing, polishing, and surface finishing to achieve a consistent, high-gloss appearance in a range of commercial machining contexts.

Fast Shipping, Global Reach, and Special Pricing

Enjoy prompt delivery-our products are shipped quickly from India, ensuring minimal downtime for your operations. FOB is available at major Indian ports, providing flexible and reliable shipping options. We export primarily to Asia, the Middle East, Europe, and Africa, maintaining the lowest price for first-class diamond burnishing tools. Request an estimate today and experience our commitment to quick response and excellent export service.

Versatile Use and Magnificent Build Quality

Our Diamond Burnishing Tools are designed for both manual and automated applications, making them ideal for use on lathes, CNC turning centers, and manual machines. Featuring a tool steel body fitted with industrial-grade polycrystalline diamond tips, they provide sublime wear resistance and precise, repeatable results. Use them for professional burnishing, polishing, and surface finishing to achieve a consistent, high-gloss appearance in a range of commercial machining contexts.

Fast Shipping, Global Reach, and Special Pricing

Enjoy prompt delivery-our products are shipped quickly from India, ensuring minimal downtime for your operations. FOB is available at major Indian ports, providing flexible and reliable shipping options. We export primarily to Asia, the Middle East, Europe, and Africa, maintaining the lowest price for first-class diamond burnishing tools. Request an estimate today and experience our commitment to quick response and excellent export service.

FAQ's of Dimond burnishing tools:

Q: How do diamond burnishing tools enhance surface quality?

A: Diamond burnishing tools achieve a high-precision, mirror-like finish on various metals without material removal, delivering exceptional smoothness (up to Ra 0.05 m) and consistent surface refinement.Q: What materials are suitable for these diamond burnishing tools?

A: Our tools are compatible with steel, stainless steel, aluminum, cast iron, and brass, making them versatile for multiple industrial applications.Q: When should I use diamond burnishing tools in the process?

A: Diamond burnishing tools are typically used during the finishing stage after machining, to polish and refine the workpiece's surface.Q: Where are these tools primarily exported?

A: We primarily export to regions including Asia, the Middle East, Europe, and Africa from India, ensuring broad global availability.Q: What are the commercial benefits of using diamond burnishing tools?

A: Key benefits include long tool life, high wear resistance, minimal coolant requirement, and precise, repeatable surface finishes-reducing production time and costs.Q: How does the interchangeable diamond tip improve the tool's usage?

A: The interchangeable diamond tip allows for easy replacement, extending the tool's service life and maintaining consistent quality without frequent tool changes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cobalt Cutting And Threading Tools Category

Face Burnishing Tools

Minimum Order Quantity : 10 Packs

Shape : Round Face

Material : Others, Premium quality alloy steel

Coating : Uncoated

Dc Grinding Wheel

Minimum Order Quantity : 10 Packs

Shape : Depressed Center (DC)

Material : Others, Aluminum Oxide

Coating : Uncoated

HSS TAPS AND DIES

Minimum Order Quantity : 100 Pieces

Shape : Round

Usage : Industrial

Product Type : HSS TAPS AND DIES

Material : Others, Metal

Gear Shaper Cutter

Minimum Order Quantity : 100 Pieces

Shape : Round

Usage : Industrial

Product Type : Gear Shaper Cutter

Coating : Polishing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS